RESEARCH AND PERFORMANCE TESTING

Technological advances mean that product quality and performance have to be constantly improved. The additives industry is therefore continually challenged to discover new molecules that improve the basic properties of oils and lubricants.

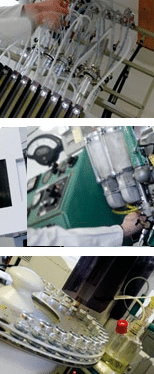

In this context, our laboratory can help you find and select the optimum formulation for your lubricants and other fluids, evaluate the performance of base oils and additives, and explore the best synergies…

CHARACTERISTICS OF OUR PERFORMANCE TESTS

Our performance tests are standardized tests that assess :

- Oxidation resistance and thermal stability properties

- Anti-wear and extreme pressure properties

- Anti-corrosion properties

- Surface properties: foaming, deaeration, demulsification

- Deposit formation (coking, varnish)

- Compatibility with elastomers and other fluids

- Volatility

- Shearing

- Etc.

In order to ensure precise and reliable results, our laboratory uses state-of-the-art techniques such as GC, HPLC, FTIR, X-Ray FS, ICP-OES, AAS, etc.

We can also perform customized tests according to your specific needs.

Our team of experienced scientists carry out research and performance tests on many types of fluids:

gear oil, compressor oil, hydraulic oil, turbine oil, engine oil, transmission oil, cutting fluid, whole oil, soluble oil, heat transfer fluid, gasoline, diesel fuel, biodiesel, heating oil, petroleum, antifreeze, aircraft de-icing, coolant, brake fluid, windshield washer fluid, dielectric fluid, grease, detergent, waste water, etc.